After I first learned about the 3D scanner and realized one of its important roles - converting real-life objects into 3D models - I had a question: How accurate is it? Like many people, once I learn about this technology, it is natural to start paying attention to what accuracy it can achieve because it certainly seems to be a simple and direct criterion to understand the quality of a scanner. Yet is this really the case? Here are all the facts about accuracy that you, as a person interested in 3D scanning, should know:

What is Accuracy?

Accuracy VS Resolution

How do we measure the accuracy of a scanner?

What factors can affect the accuracy of a scanner?

Is accuracy important?

What about the Accuracy of Einstar?

What is Accuracy?

Accuracy is defined as "the degree to which a measurement result conforms to the correct value or standard" and is essentially the closeness of a given set of measurements to the agreed value/object's true value. In general, accuracy is the result of measurement under ideal conditions and cannot be judged by visual effects alone.

Accuracy VS Resolution

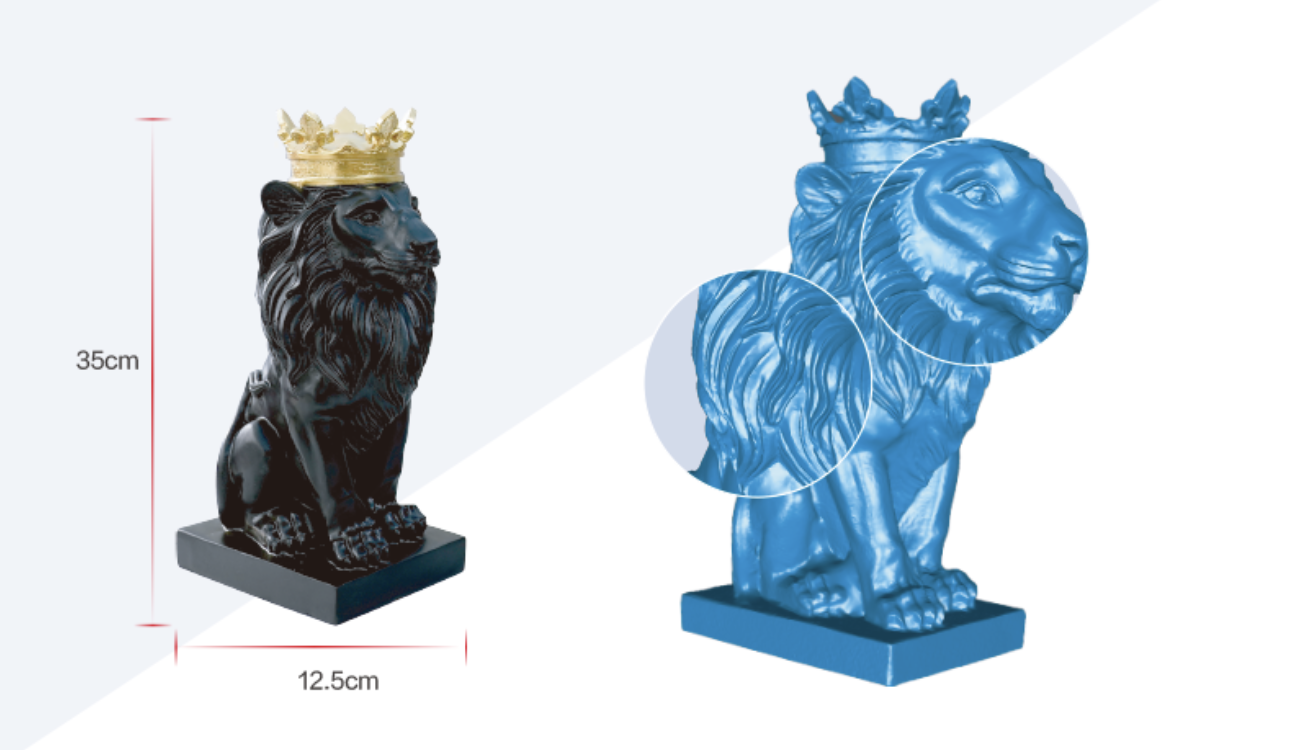

Resolution is defining the point distance which the scanner is capturing. The smaller the distance, the higher the resolution, and more density points of the data for better detail.If you select low resolution, the point distance is bigger, less points generated. We suggest to set low resolution when scan large size object for better scanning experience.

Einstar's resolution is variable, the best resolution can reach to 0.1mm

Portrait mode resolution:0.2mm ~ 3.0mm (recommend a resolution of 1.0 mm)

Object mode resolution:0.1mm ~ 3.0mm (recommend a resolution of 0.5 mm)

So, Accuracy and Resolution represent differently, and if you are unsure of the level of accuracy or resolution you need, our team of measurement experts are here (embedded link of sales@shining3d.com) to help.

How do we measure the accuracy of a scanner?

Accurate results require multiple scans of the calibration artifacts (usually a certified ball bar) at different angles under ideal environmental conditions according to the VDI/VDE 2634 standard. Each scanner in the EinScan Pro Series, EinScan H Series follows the same standards to ensure accuracy is controlled within the listed values.

As the leading drafting party of the industry standard of "Chinese Structure light 3D measurement system", SHINING 3D has always been serious about accuracy. Unlike "single frame accuracy", we tend to test "accuracy of aligned data" in a professional measurement way. Because 3D models are usually stitched together from multiple scanned frames, in most cases the accuracy one is discussing is not the highest accuracy that can be obtained from a single scan.

What factors can affect the accuracy of a scanner?

As mentioned above, accuracy testing is generally performed in an ideal environment, it is easy to see that many factors can influence the results of an accuracy test, such as operator skill level, lab temperature and humidity, vibration, calibration, surface texture, surface color, part cleanliness, etc.

Does accuracy matter?

To understand this question, it is most important to understand the specific application of the scanned model. In 3D scanning, accuracy is especially important for industrial applications, such as quality inspection and reverse engineering.

And for applications that may only use 3D data visually, such as data archiving and virtual displays, accuracy may not be a very important factor. Will Co, for example, used Einstar he scanned the human face in order to make a Halloween mask. To accommodate the size of the face, such an application undoubtedly requires a certain level of accuracy in the scan to restore the details of the face, but it does not require as high a fit as a high precision industrial inspection. Einstar is certainly welcomed in such scenarios.

Einstar is also accurate enough for 3D printing, and you can check out 3D Prints&Builds' video in which he scans a figurine about 7 cm tall and prints it out.

For more scanned data: 3D Gallery

For more application scenarios: Applications

What about the Accuracy of Einstar?

To make the Einstar more accessible, unlike other EinScan models where we perform accuracy tests on each scanner, we perform random accuracy tests on the Einstar. However, each calibration plate of the Einstar in glass material, which assures the stablity and consistency, is measured in the SAME way as a professional scanner to help Einstar achieve submilimeter accuracy. Users can control good results from their scan data by calibrating with the Einstar when needed.

Professional scanners usually have a high level of accuracy. When accuracy is a key factor in your application, it is always worth investing in a professional scanner. A less expensive scanner can also be the right choice to provide good data for your purposes. Choose the right scanner for your application, not just based on a spec sheet.

If you need any help with scanner selection, please contact sales@shining3d.com. There are many professionals there to answer your questions about accuracy and model selection!

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.